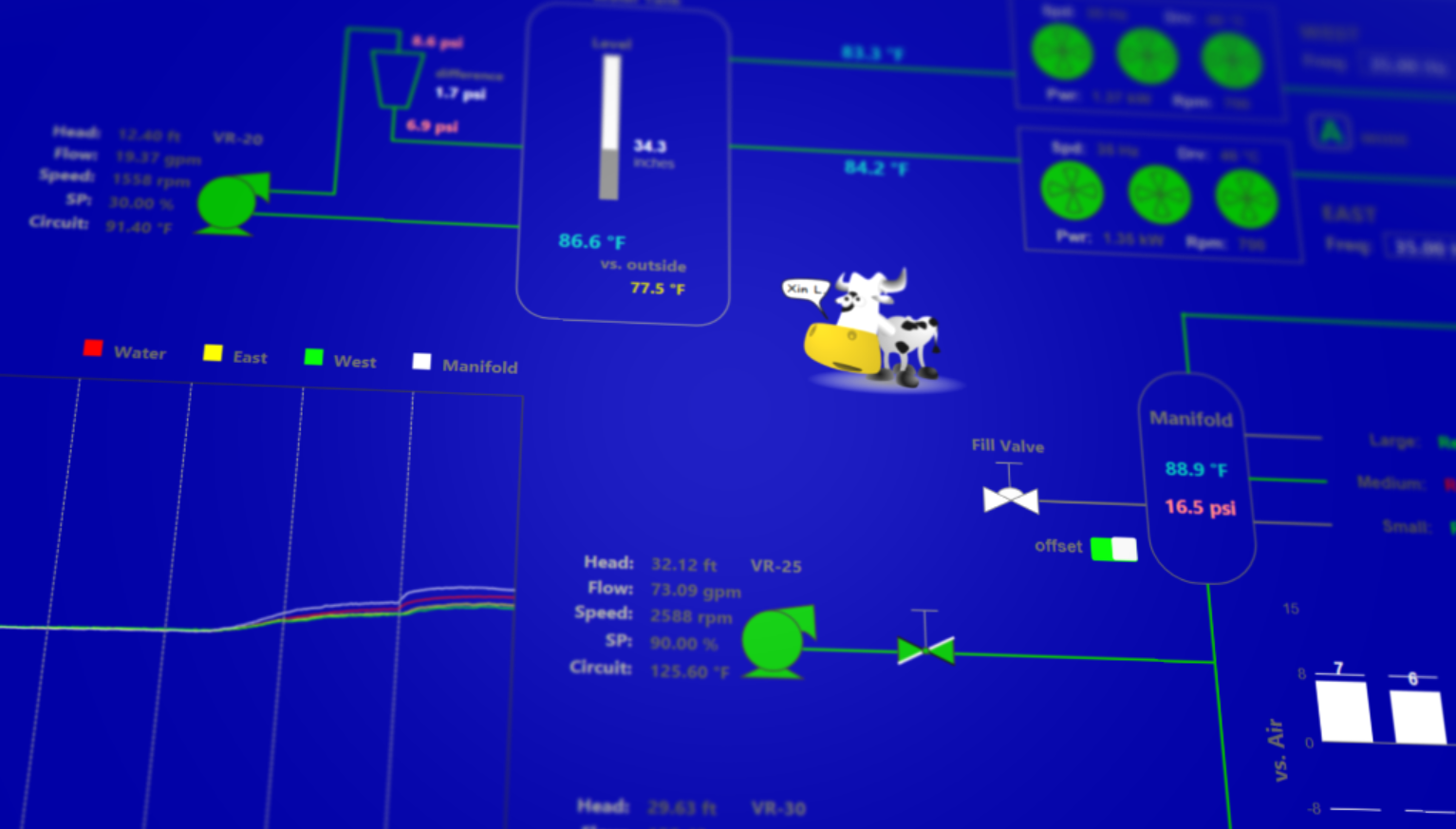

This advanced water cooling control system continuously monitors and adjusts various parameters to efficiently regulate the temperature of the cycling water used in industrial processes like autoclaving. The intelligent system employs custom algorithms to analyze data from multiple sensors, including water temperature, room temperature, and outdoor air temperature.

Based on these inputs, the system dynamically adjusts the speed of the cooling fans to precisely modulate the water temperature as needed while optimizing energy usage. The user interface provides a comprehensive overview, displaying key metrics such as water level, pressure differentials, pump speeds, and cooling fan power consumption.

The system's dual-loop design incorporates an East and West circuit, each with its own temperature, speed, and power readings. This redundancy ensures uninterrupted operation and enhances reliability. The manifold section displays the status of the fill valve and offset pressure, further illustrating the system's self-correcting capabilities.

With its advanced automation, energy-saving features, and real-time monitoring, this water cooling control system exemplifies the cutting-edge technology used to maintain precise temperature control while promoting sustainability and operational efficiency.

This advanced water cooling control system continuously monitors and adjusts various parameters to efficiently regulate the temperature of the cycling water used in industrial processes like autoclaving. The intelligent system employs custom algorithms to analyze data from multiple sensors, including water temperature, room temperature, and outdoor air temperature.

Based on these inputs, the system dynamically adjusts the speed of the cooling fans to precisely modulate the water temperature as needed while optimizing energy usage. The user interface provides a comprehensive overview, displaying key metrics such as water level, pressure differentials, pump speeds, and cooling fan power consumption.

The system's dual-loop design incorporates an East and West circuit, each with its own temperature, speed, and power readings. This redundancy ensures uninterrupted operation and enhances reliability. The manifold section displays the status of the fill valve and offset pressure, further illustrating the system's self-correcting capabilities.

With its advanced automation, energy-saving features, and real-time monitoring, this water cooling control system exemplifies the cutting-edge technology used to maintain precise temperature control while promoting sustainability and operational efficiency.

Read Next

Caddy as the Front Door of My Homelab

Homelab: Self-Hosting GitLab

Homelab: Shadowsocks + VLESS (TCP+TLS)

Homelab: WireGuard VPN (Docker)